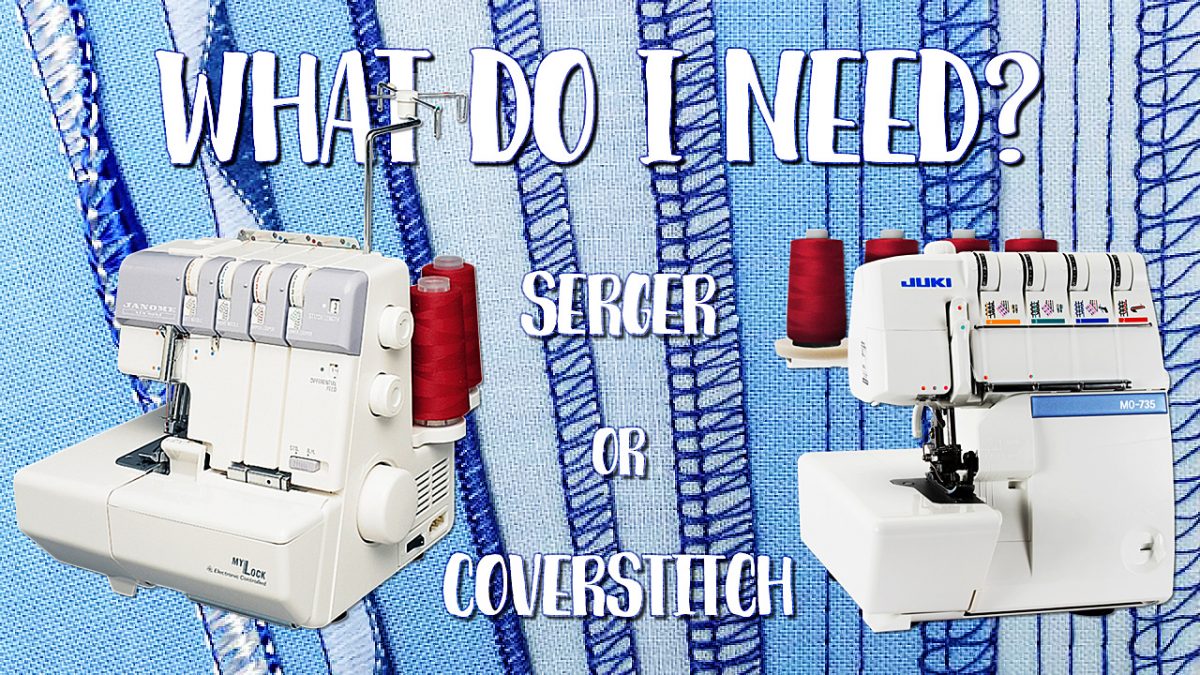

Serger vs. Coverstitch Machine — Do you need both?

What is the difference between a serger, an overlocker, and a cover stitch machine?

Serger vs Coverstitch: The Serger / Overlocking Machine

A serger and an overlocker are different names for the same machine. Americans generally refer to these as sergers, and nearly everyone else refers to them as overlockers. A serger performs an overlocking stitch, which is really more like knitting than sewing.

Overlocking, or serging, trims and binds seams so that the fabric can not unravel. It professionally finishes the insides of garments. There are rare occasions when one might use a serger to embellish outside seams or to finish hems, such as with rolled hemming, but in general the serger or overlocker is used in construction rather than finishing.

The serger is quite a different machine than a sewing machine, and requires threading of three or four pathways, including two loopers. These loopers accomplish the knitting involved in the overlock stitch. A serger also has knives, which cut seam allowances as it serges them. This machine does not replace the sewing machine, but works beside it accomplishing tasks no sewing machine can do.

The Janome 634D is my choice recommendation for the serger to buy. Here is my review of this model.

Serger vs Coverstitch: The Coverstitch Machine

A coverstitcher really takes all the trouble and error out of this otherwise tricky task.

The coverstitch machine is the star of the machine line-up for finishing tasks. A coverstitch machine beautifully finishes hems on most types of garments, especially knits. Many would-be seamstresses shy away from sewing knit garments because sewing stretchy fabrics using a sewing machine alone is decidedly tricky. While a serger is certainly helpful (some would say essential) in sewing with knits, nothing is as helpful for working with knits as a coverstitch machine. These sweeties allow knits to be turned and hemmed beautifully and quickly, with a stretchy seam that will not break.

For me, hems are perhaps the most difficult task in garment sewing, but the only reason I feel this way is because my machine arsenal has not previously included a coverstitch machine. A coverstitcher really takes all the trouble and error out of this otherwise tricky task. And speaking of tricky tasks, a coverstitch machine can also attach lace, elastic, or other trim to any garment in a hurry, again with a stretchable seam that will not break. It can even take the trouble out of attaching bindings.

When looking at the serger vs coverstitch machine, a coverstitch machine looks more like a sewing machine than a serger does. And a coverstitch machine is similarly uncomplicated. A coverstitcher only has one looper, and it doesn’t have any knives. This makes the threading of a coverstitch machine straightforward and easy to do. You may leave the coverstitch machine threaded and waiting to perform its hemming whenever you need it. I love the simplicity of a machine that can sit patiently waiting to perform its job beautifully and quickly. Having a coverstitch machine waiting to hem garments means you will actually make garments, rather than being daunted by the trouble of hems!

Coverstitch Machines: Simple yet Versatile

A coverstitching machine is versatile, despite its simplicity. With most, you can use one, two, or three needles. There are also a couple of different configurations that you can use with two needles, to make narrow or wide rows of hem stitches. A single needle can be used to knit the chainstitch, which is a beautiful stretchy seam. A chainstitch can be used for both utility and decorative effects.

I recommend the Janome 1000CPX CoverPro as the best coverstitcher to buy. As I have said before, I really trust Janome. I prefer this brand as being the best value for user-friendly, high-quality machines.

You can begin using your coverstitch machine immediately, and use it often, without ever needing to buy attachments or extra feet. However, you can get the most from your coverstitcher and do lots of things with different attachments. A clear foot is nice to have. You can get a binder attachment which will neatly attach binding to most any project. You can also buy cording and gathering feet, a pintucking bar, a feller, belt looping folder, and more. None of these are necessary, although you will really appreciate having a clear foot.

Serger vs Coverstitch: Combo Models

One choice when thinking about the serger vs. coverstitch machine is to buy one machine to perform both functions. For folks without the room for multiple machines, there are combination models that will perform both overlocking and coverstitching. This may be a sensible choice for you, rather than buying two machines.

I recommend this choice only for someone with quite limited space or budget; my preference is to have separate serger and coverstitch machines if possible. That’s because it is more expedient to have each machine set up and ready to do its job. Then you can just move back and forth quickly between the two machines as you need each. This is easier than having to reconfigure a complicated serger when moving back and forth between tasks. I’m told it really only takes a moment and is an easy chore to do, however. I know many sewists love their combo serger/ coverstitch machine and use it regularly for both tasks.

A combo model is a good budget choice for people who want to make garments and need both overlock and coverstitch capability, without spending a lot of money.

Be aware that this choice is a compromise. A serger with coverstitching capability won’t have a free arm. This feature makes a separate coverstitch machine a useful joy for hemming. Nor can combo machines perform as perfect an overlock or coverstitch as separate machines will. To get the best of both worlds, buying a separate serger and coverstitch machine is the way to go.

Serger vs Coverstitch: You Need Both!

So now you know that it is not a question of which machine to choose, serger vs. coverstitch machine. To beautifully and professionally produce and finish quality garments, you need both. You can choose to satisfy this need with a complicated serger that performs both functions. Or you can satisfy both needs with a separate serger and coverstitch machine. Either way, upgrade your machine arsenal and uplevel your sewing by including overlock / serging and coverstitch capabilities to your lineup. You and your wardrobe will be glad that you did!

Overlocker / Serger Vs Coverstitch Machine — You want both!